Our high quality AB Two Layer Film Blowing Machine, developed by Leynix, is engineered for the production of plastic laminated films using low-density polyethylene (LDPE), high-density polyethylene (HDPE), linear low-density polyethylene (LLDPE), and more. This versatile machine finds widespread application in packaging liquids, printed base materials, export products, and various industrial applications.

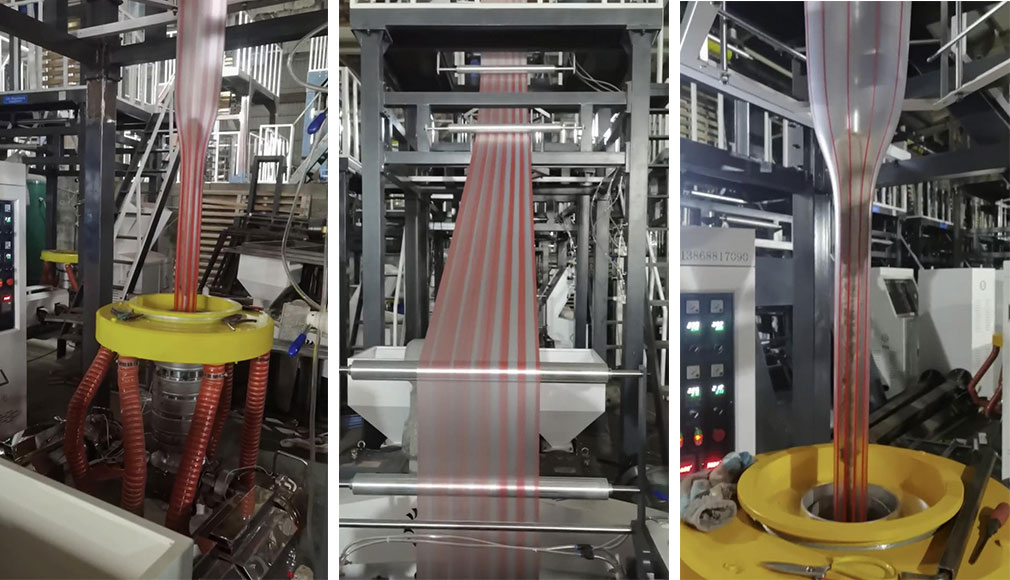

The AB Two Layer Film Blowing Machine features dual extruders and a double-layer structure die-head. By introducing two similar or different materials into the extruders simultaneously, it creates a co-extrusion composite film that significantly enhances the film's physical properties. This includes improved strength, barrier properties, and air tightness.

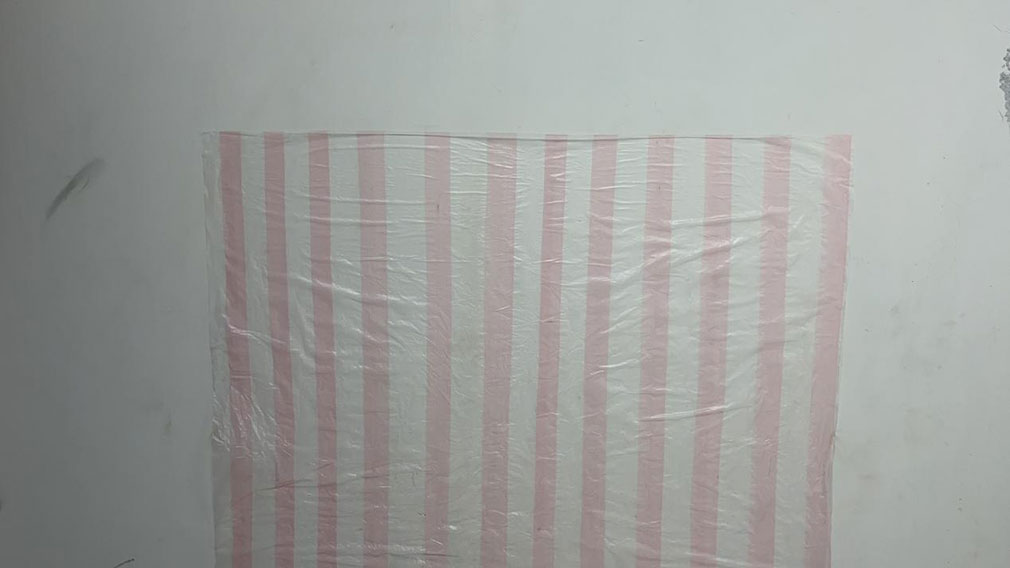

Leynix's AB Two Layer Film Blowing Machine is specifically designed for blowing high-density polyethylene, low-density polyethylene, and linear low-density polyethylene. The resulting films are widely utilized in the production of courier bag films and two-color films.

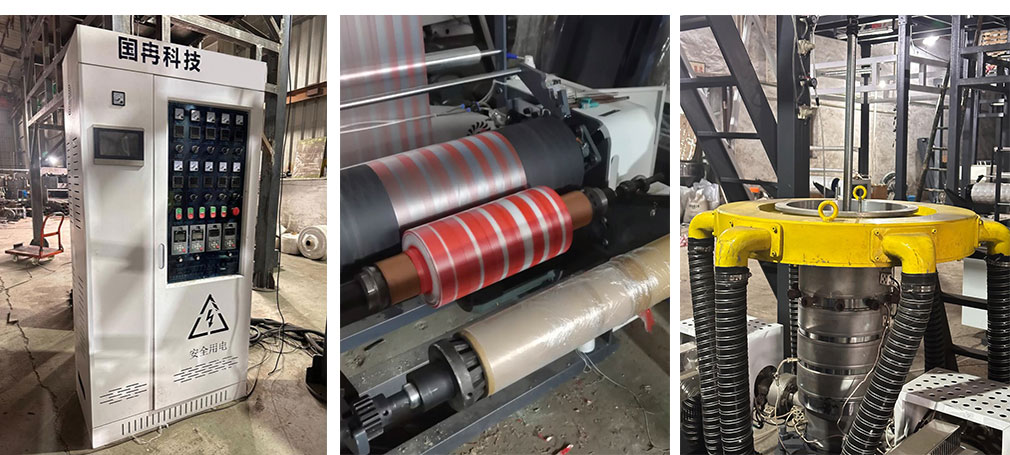

All main machines incorporate screws known for their exceptional hardness and wear resistance. This design allows for efficient plasticization of a large quantity of particles, even in high-speed and high-pressure environments.

The die-head adopts a special two-layer cone structure. Through meticulous polishing and coating, each runner possesses self-cleaning capabilities under the high-pressure and high-speed scouring from the screws. This innovative design minimizes waste during particle replacement and reduces maintenance downtime.

Choose Leynix's AB Two Layer Film Blowing Machine for a technological edge in film production, ensuring superior physical properties and application versatility.

| Model | GR60-1300ABA |

| Maximum Film Width | 1200(mm) |

| Minimum Film Width | 200(mm) |

| Thickness of film | Single Face 0.002s-0.15s(HDPE) |

| Maximum output | 120kg/h |

| Dimension | L5200*W3200*H5400 |

| Screw Diameter | ø60 |

| Screw Length-diameter ratio | 32 : 1 |

| screw Material | 38CrMoAIA |

| Reducer | 173 |

| Extruder main motor | 30KW |

| Screw Speed | 0-120min |

Leynix AB Co-Extrusion Color Strips Film Blowing Machine is used to blow plastic composite films such as low density polyethylene (LDPE), high density polyethylene (HDPE) and linear low density polyethylene (LLPE). It is widely used in liquid packaging, printing substrates, export product packaging, industrial product packaging, and civilian industrial product packaging such as food, fruit, clothing, textiles, and daily necessities. The barrel and screw of the extruder are made of high-quality alloy steel, which has been nitrided and precision processed to have the best hardness and corrosion resistance.