The Leynix high quality Carry D-Cut Bottom Sealing Carrier Plastic Poly Bag Making Machine is a specialized piece of equipment designed for the efficient production of plastic poly bags with a D-cut handle and a bottom sealing feature. Let's explore its key features and functionalities:

D-Cut Handle Production: The machine is equipped to create poly bags with D-cut handles, offering convenience for carrying and handling.

Bottom Sealing Capability: It has the capability to seal the bottom of the plastic bags, ensuring a secure and durable closure.

Carrier Bag Manufacturing: Specifically designed for the production of carrier bags, commonly used in retail and various industries.

High-Speed Operation: Likely to operate at high speeds, contributing to increased production efficiency.

Advanced Control System: Incorporates an advanced control system for precise and reliable bag manufacturing.

| Model | GT500*2 |

| Max. Width | 180-450mm×2 |

| Max. Length | 280-700mm*2 |

| Thickness | 0.01-0.05mm |

| Speed | 100-400pcs/min*2 |

| Lines | 2 |

| Air Pressure | 10HP |

| Total Power | 16KW |

| Weight | 2700kg |

| Dimension(L*W*H) | 6500*2800*1900mm |

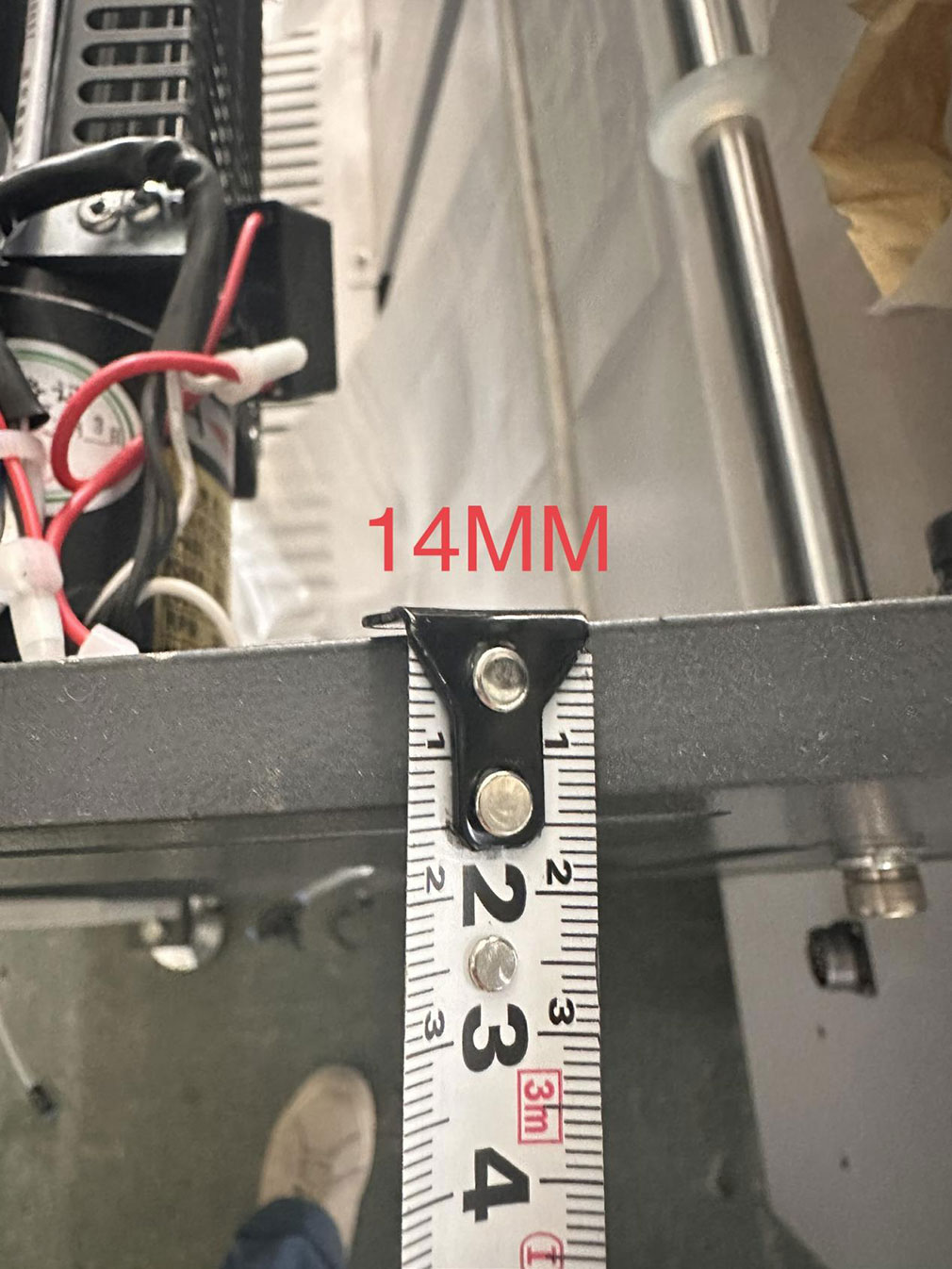

Steel plate 14mm

Inovance, Servo+PLC, intelligent digital display

Leynix high quality Carry D-Cut Bottom Sealing Carrier Plastic Poly Bag Making Machine Applications:

Retail Packaging: Ideal for the production of plastic bags commonly used in retail settings for carrying goods.

Grocery Bags: Suitable for manufacturing plastic bags used for carrying groceries and other items.

Customized Branding: Offers the potential for customization, allowing for the incorporation of brand logos or promotional messages on the bags.

Leynix high quality Carry D-Cut Bottom Sealing Carrier Plastic Poly Bag Making Machine Considerations:

Material Compatibility: The machine is designed to work with specific types of plastic materials commonly used for poly bag production.

Operator Training: Operators may require training to operate the machine effectively, ensuring optimal performance and quality output.

Maintenance Requirements: Regular maintenance is crucial to keep the machine in optimal working condition and to prevent downtime.