As a distinguished Non-woven high-speed T-shirt Bag Making Machine supplier with a state-of-the-art factory, Leynix is a trusted leader in providing tailored solutions for industrial applications. The Non-woven High-Speed T-shirt Bag Making Machine by Leynix exemplifies precision and innovation, ensuring the production of high-quality and customized non-woven T-shirt bags with remarkable speed. Setting industry benchmarks, Leynix delivers top-tier machines that meet the highest quality standards and cater to unique customization needs.

This machine is an ideal equipment for non-woven flat bags, U-cut bags, string bags, T-shirt bags, etc. Automatic punching, automatic counting alarm, automatic feeding, automatic stop when labels are lost.

| model | WFB-D600 | speed | 50-120pcs/min |

| Maximum material width | 200mm-1200mm | total power | 10KW |

| Bag thickness | 18-90g | weight | 2800kg |

| Maximum bag length | 200mm-999mm | Maximum bag making width | 200mm-600mm |

| dimension | 10800*1800*2000mm | ||

| The heat sealing part adopts 4 sets of ultrasonic independent control. When making small bags, unnecessary ultrasonic waves can be turned off to save energy. Shock absorption can reduce horn wear and extend service life. |

| High-quality aluminum rollers provide smooth feeding and reduce fabric elongation, especially suitable for thin fabrics |  |

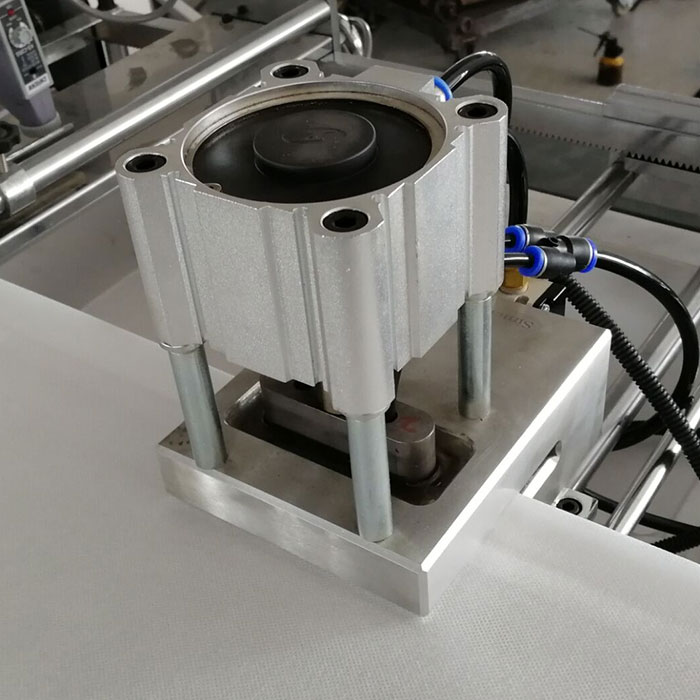

The cylinder automatically lifts and lowers, saving effort in discharging materials and easy to operate. |  |

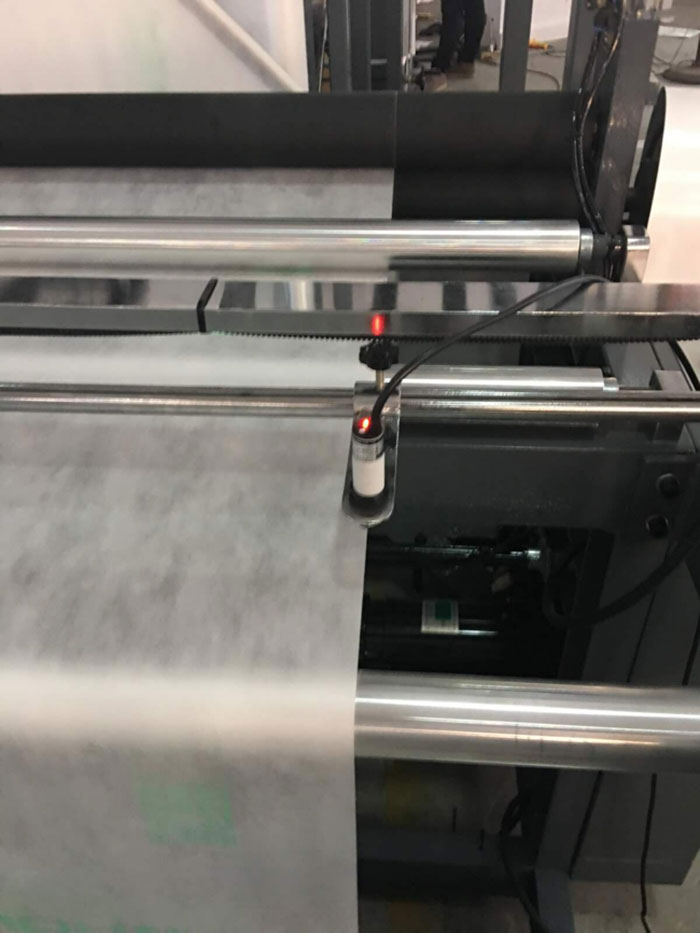

| High-quality sensors align the fabric to make the bag flat |

| Proximity switch, automatically stops when the material is almost used up |  |

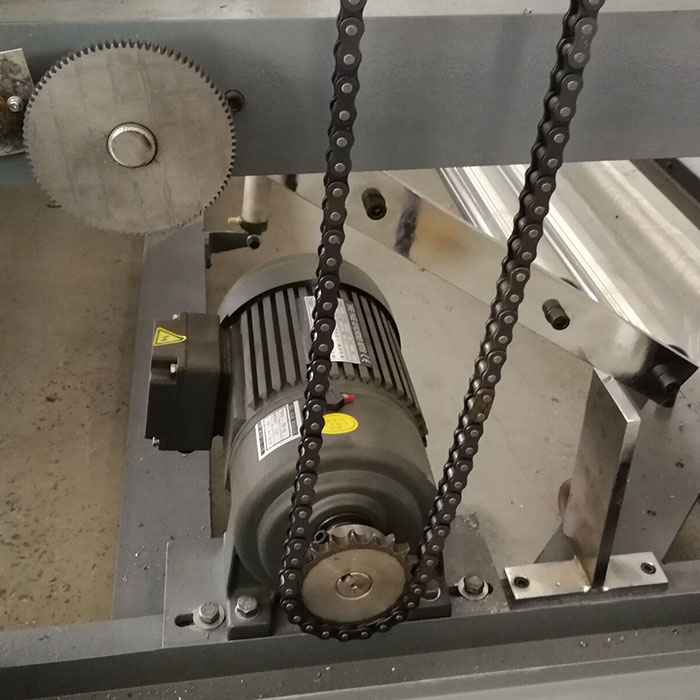

| Frequency conversion motor feeding, synchronously controlled with the main motor |

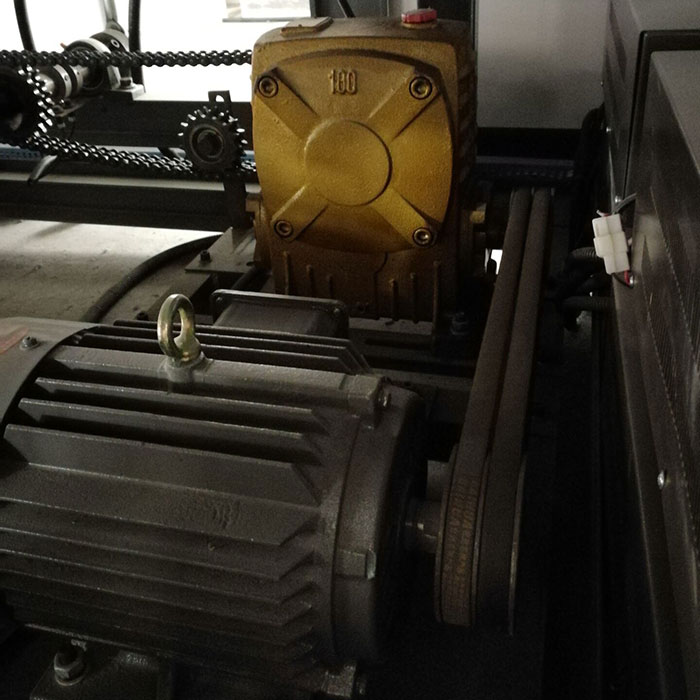

| The main motor adopts variable frequency motor, which saves energy and is easy to operate |  |

| Set up the inverter to control the variable frequency motor |

| Insert device to make gusset bags, such as bottom gusset bags, U-shaped bags, box bags |

| Roller ultrasonic side sealing, (for U-shaped cutting bags) |  |

| The blower will pick out the waste fabric when making U-shaped bags. |

| Dual stepper motor pulls cloth, lower elongation rate, and more accurate bag length control |

| Stepper Motor Driver |  |

| D-cut puncher |

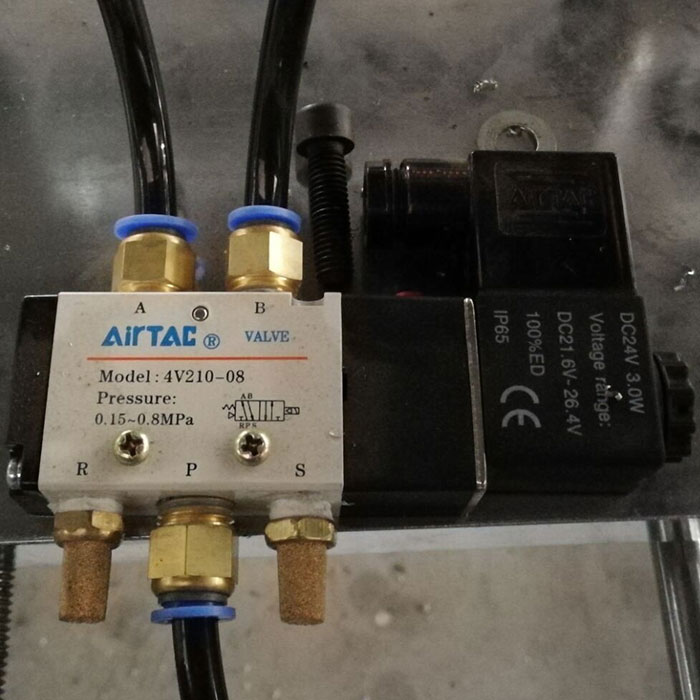

| The electromagnetic valve Airtac brand,made in Taiwan |

| Electrical switch Schneider |  |

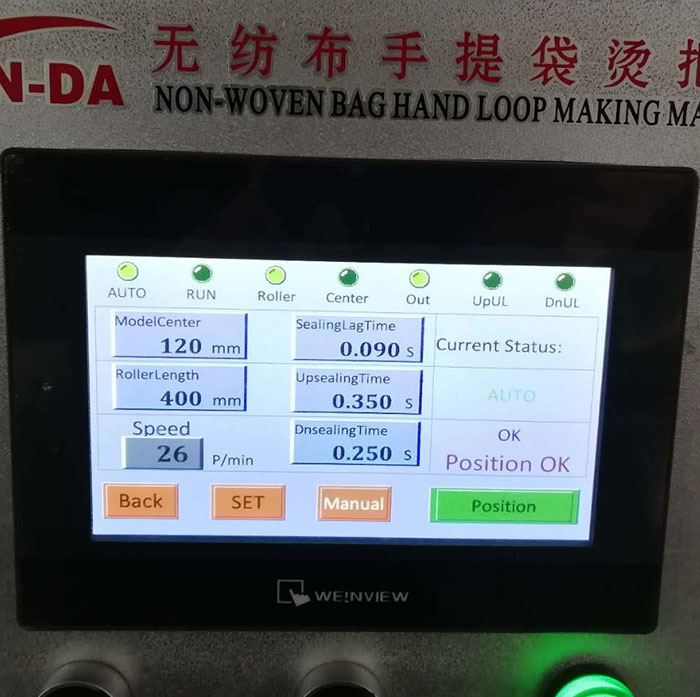

| Touch screen Weinview brand Made in Taiwan |

| Main Motor | main motor | LIBIAO (CHINA) |

| stepping motor | SOYO(CHINA) | |

| electric | stepping motor driver | (CHINA) |

| PLC | PANASONIC (JAPAN) | |

| Variable frequency drive | CHINA | |

| Low voltage electrical switch | CHINT&SCHNEIDER | |

| sensor | CHINA | |

| cylinder | main cylinder | AIRTAC(TAIWAN) |

| Bearing | main bearing | NSK,SKF |

| ultrasound | Round head & square head | Toshiba chip |

| touchscreen | Weinview (TAIWAN) |