Leynix proudly presents the High Speed ABA Double Layer Film Blowing Machine, a cutting-edge solution designed to revolutionize film production processes. As a leading manufacturer based in China, Leynix is committed to delivering state-of-the-art machinery that sets new standards in efficiency, speed, and quality.

| Technical Parameters | |

| Model | GR70-1500ABA2F |

| Maximum Film Width | 1400(mm) |

| Minimum Film Width | 200(mm) |

| Thickness of film | Single Face 0.002s-0.15s(HDPE) |

| Maximum output | 200kg/h |

| Dimension | L5200*W3200*H6400 |

| Screw Diameter | ø70x2 |

| Screw L/D | 32 : 1 |

| screw Material | 38CrMoAIA |

| Reducer | 200x2 |

| Extruder main motor | 45KWx2 |

| Screw Speed | 0-120min |

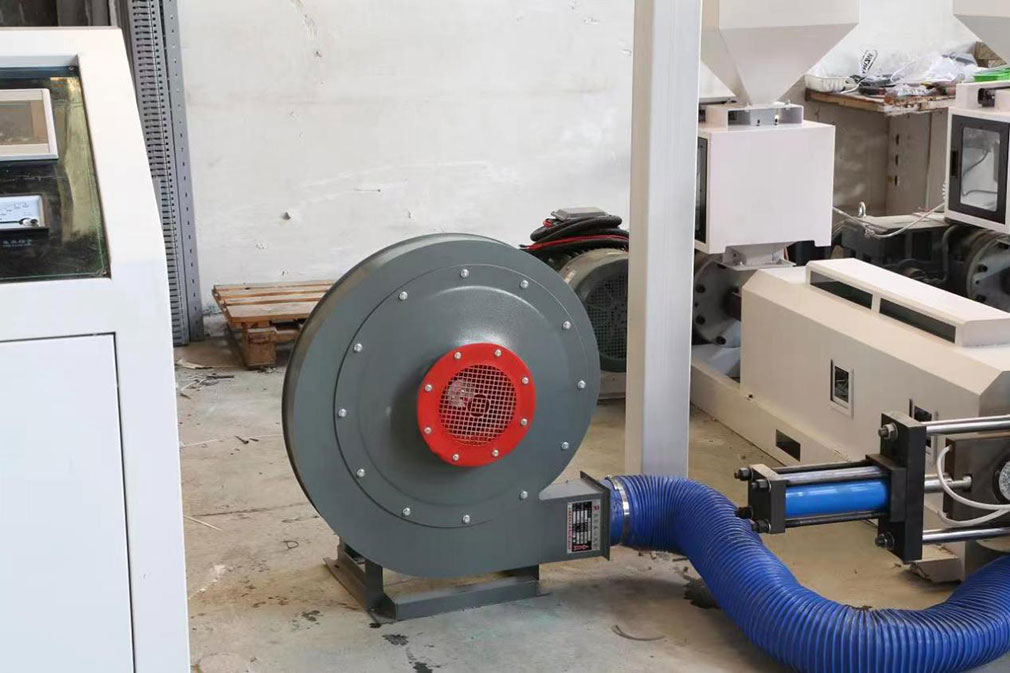

7.5KW High power high pressure blower

Intelligent digital display power distribution cabinet

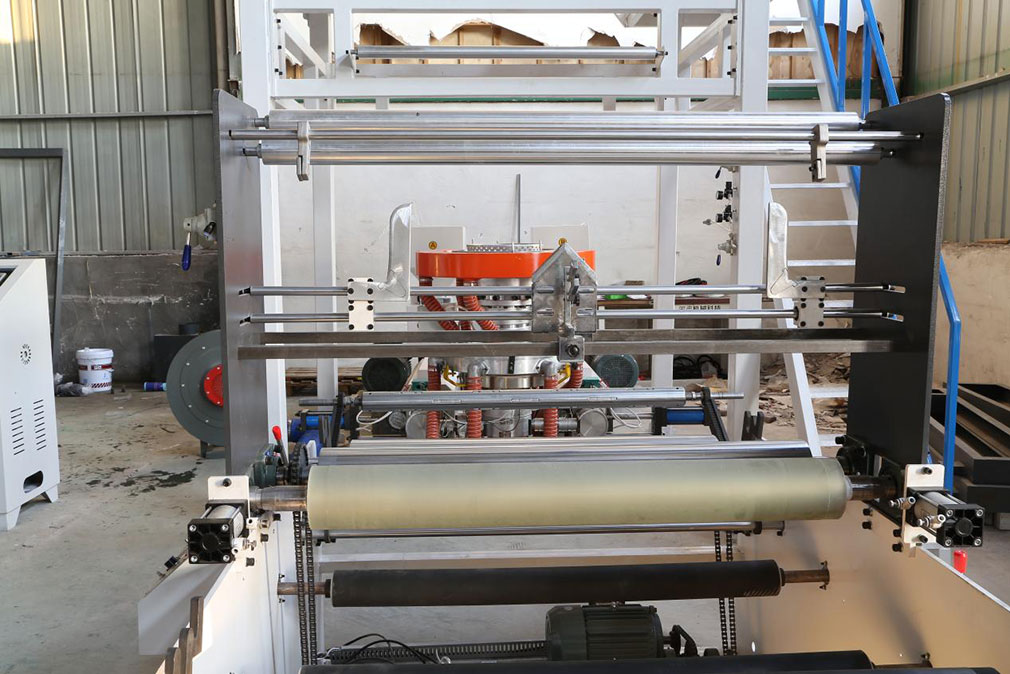

Equipped with a cutting device, double cutting and double rewinding

Back-to-back double-station winding

Equipped with 4 air shafts

Double alloy screw with rotating film head, good plasticization and high output

Wenzhou Leynix machinery is a High Speed ABA Double Layer Film Blowing Machine manufacturer from china, our business is mainly to produce and sell different type Film Blowing Machine, We also can customized product according to the client's requirement. We are always try our best to become the good Film Blowing Machine manufacturer, Welcome the customer from all over the world to contact with us. If you want more detailed information of this product or related problems, please contact with us, we will reply as soon as possible (general in 24 hours).

It is used for blowing high-low pressure polyethylene, which has been widely used for producing laminating film, packing film, agricultural covering film, bag or film for textile and clothing and other packing material. The main motor adopts variable frequency motor to improve the speed regulating stability and save electricity by 30%. The screw and material barrel adopt 38 chrome-molybdenum aluminum which has been nitrogen treated and the traction frame adopts lifting type. No matter what size the film is, it can achieve the best effect of cooling.

1.Auto loader

2. Film surface treater

3. Rotary die head

4. Air compressor

5. Mechanics screen changer

6. Double wind