| twin screw extruder | |

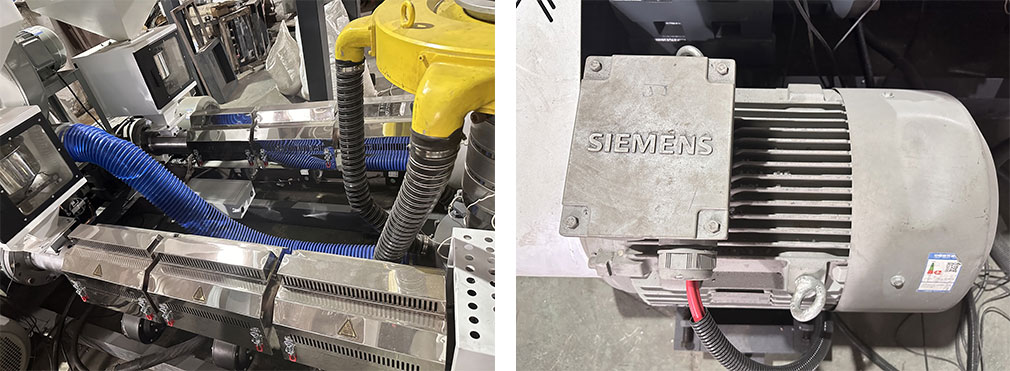

| Hard tooth surface gearbox | 173 type gearbox (national standard) X2 |

| Barrel screw | GT-55X2 |

| L/D | 32\1 |

| Screw speed | 0-120 (min) |

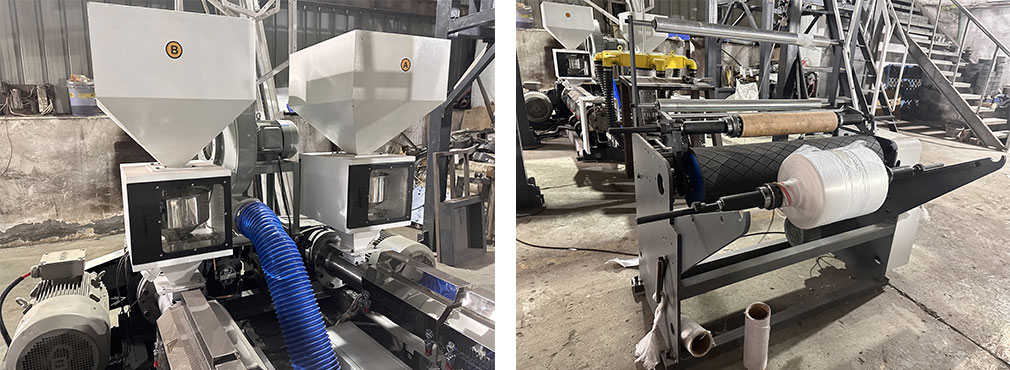

| film width | 800(mm) |

| Film minimum width | 100(mm) |

| film thickness | Single side 0.15s (HDPE) |

| Film minimum thickness | Single side 0.002s (HDPE) |

| Extrude maximum output | 100kg/h |

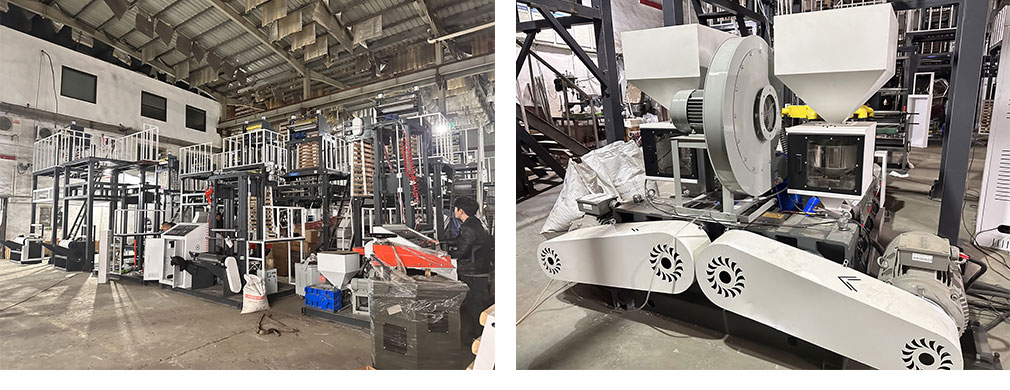

| Rack (150*150 square tube) | single layer platform |

| Dimension | L5000*W2800*H5400 |

The Leynix High Speed Monolayer ABA Film Blowing Machine is an advanced piece of equipment designed for the rapid and efficient production of ABA-type plastic films. Let's break down its key features and capabilities:

Monolayer ABA Technology: Incorporates ABA technology, which refers to the use of three layers in the film structure (A-B-A), enhancing the film's properties such as strength, flexibility, and barrier characteristics.

High-Speed Operation: Engineered for high-speed film production, contributing to increased output and efficiency.

ABA Layer Configuration: The ABA structure typically involves a central layer (B) sandwiched between two outer layers (A), each serving specific purposes to enhance the film's overall performance.

Precision Extrusion: Utilizes precision extrusion processes to ensure uniform thickness and quality of the ABA film.

Advanced Cooling System: Likely includes an advanced cooling system to rapidly cool and set the molten plastic, allowing for efficient production.

Efficient Cooling Technology: Advanced cooling technology contributes to faster production cycles and improved film quality.

Automated Controls: Incorporates automated controls for precise adjustments and monitoring of the film production process.

Enhanced Output: Designed to maximize output while maintaining the desired film quality, contributing to overall efficiency.

Packaging Industry: Suitable for producing ABA films used in various packaging applications, offering enhanced strength and barrier properties.

Industrial Films: ABA films are often used for industrial applications where specific film properties are required, such as in construction or agriculture.

Custom Film Solutions: Provides flexibility for manufacturing customized film solutions tailored to specific industry requirements.

Material Compatibility: The machine is designed to work with specific plastic materials suitable for the ABA film structure.

Operator Training: Operators may require training to effectively operate and monitor the machine for optimal performance.

Maintenance Requirements: Regular maintenance is essential to ensure the machine's longevity and consistent performance.

Bag weight display, touch screen adjustment, connection to meter weight, and control of winding

Double air outlet high-pressure air ring, good stability, high transparency and good cooling effect